Desktop Semi-Automatic siomai Machine Revolutionizes Traditional Cuisine Production, Boosting Efficiency in Catering Industry

With the booming global Chinese food market, Shaomai (steamed dumplings), as a classic dim sum, has seen surging demand. Traditional handmade production faces challenges such as low efficiency, high costs, and inconsistent quality. Recently, the Desktop Semi-Automatic Shaomai Machine launched by Ningbo Jiangbei Fuxin Food Machinery Co., Ltd. has become a game-changer in the catering industry, redefining the future of food production with its efficiency, convenience, and intelligentize features.

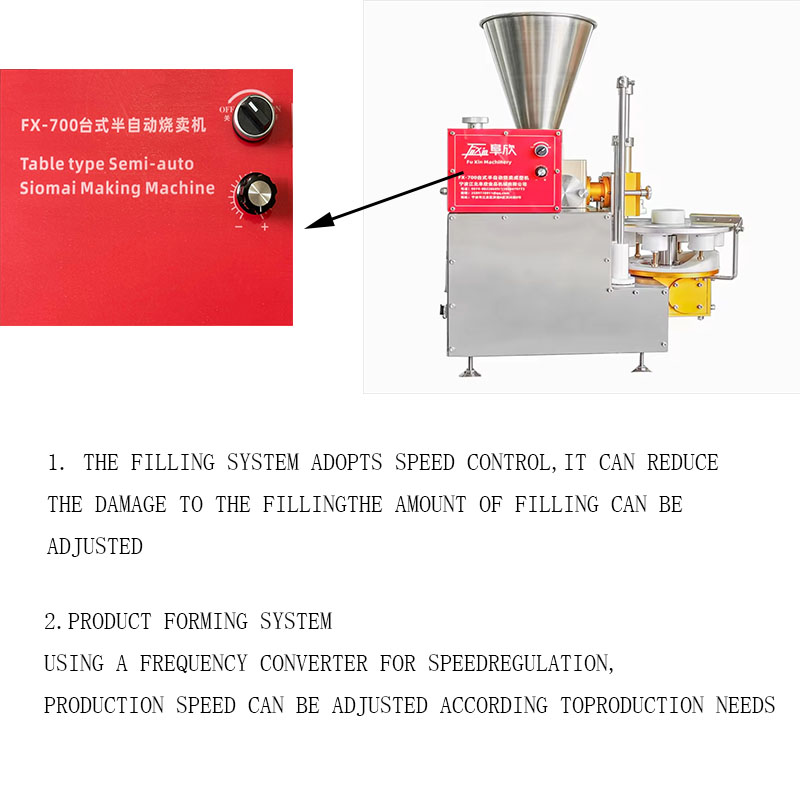

Core Advantages & Technological Highlights

- User-Friendly Operation & High Efficiency

The machine simplifies the workflow: users only need to load dough and fillings into designated containers, adjust parameters, and press start. It can produce hundreds of Shaomai per hour, significantly outperforming manual methods, making it ideal for busy restaurants and food factories. - Precision Quality Control

Equipped with smart parameter settings, the machine ensures uniform size, shape, and filling distribution for each siomai, enhancing product consistency and reducing waste caused by human errors. - Versatility & Flexibility

Compatible with various dough types (e.g., dead dough, yeast dough), the machine can produce diverse products like meat buns, vegetable buns, and soup dumplings. Users can also adjust skin-to-filling ratios to meet personalized tastes . - Cost Savings & Hygiene Standards

Made of food-grade stainless steel, the machine meets strict hygiene requirements while cutting labor costs by up to 30%, according to industry estimates .

Market Response & Future Prospects

The machine has been widely adopted by Chinese restaurant chains, food processors, and even home kitchens. CCTV’s “I Love Invention” program previously featured similar automated Shaomai machines, highlighting the industry’s demand for technological innovation. Fuxin Company announced plans to integrate IoT and AI technologies into future models, aiming to achieve full automation in traditional dim sum production.

Post time: Mar-10-2025